|

Gearbox and Transmission

The gear ratio's given in the Norton Maintenance

and Instruction Manuals and as often found in various contemporary

books are slightly confusing when you are looking for a proper

gearbox for your bike. The ratio's given are basically the ratio's

of the entire transmission system from engine sprocket to rear

wheel drum mounted sprocket, and not of the gearbox itself. Civilian

16H and Big4, and WD16H gearbox shells were all identical (casting

number N8001E) and do not have

any identifying marking on them to tell you what it is.

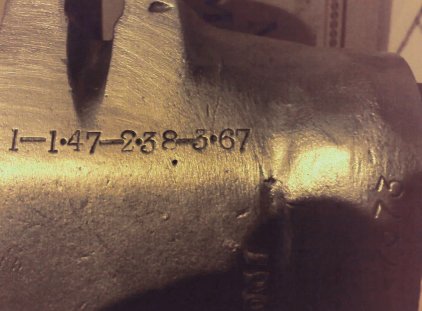

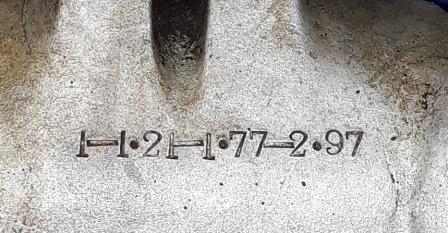

War Department Big4 gearboxes are however indentified by the gearbox

ratio's hammered into the rear of the shell. Picture below shows an

example of such marking.

As the majority of gearboxes do not have such markings, its believed

that only the boxes deviating from standard are actually identified

by these markings.

Its likely that Racing gearboxes will also have the ratio numbers

added to them, but I have no personal experience of this. The

ratio's will however be lower on them than on the standard

gearboxes.

Especially for the Big4 restorers its

difficult to find a correct bearbox because there are still loads of 16H gearboxes around, but

not many Big4 gearboxes.

It has to be kept in mind however that if you are restoring a prewar

civilian Big4, the civil/military 16H gearbox is correct.

Only the military Big4 received a gearbox with a different, lower,

gearing to haul along the not so very light sidecar through loads of

mud.

Pictures above and table below showing the different gear

ratio's of the different gearboxes and of the total transmission of

the WD16H, WDBig4 and the civilian 4 speed gearboxes (upto 1940) built by

Norton between "model year" 1935 and 1945.

Gearbox ratio's

|

Model |

WD16H

and civil 16H/Big4 |

WDBig4

|

|

GEARBOX RATIO'S |

|

First |

2,97 |

3,67 |

|

Second |

1,77 |

2,38 |

|

Third |

1,21 |

1,47 |

|

Forth |

1,00 |

1,00 |

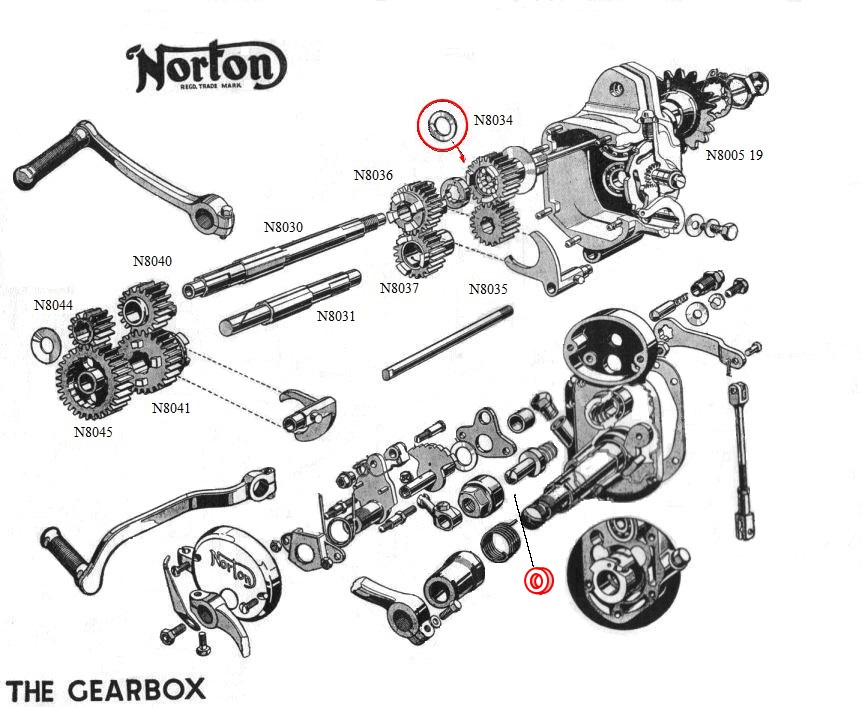

Survey of gearbox internals

showing

identification numbers as given on the individual gear wheels,

number of teeths and Norton spare part

number, usually engraved into the gear wheel by the N80xx number.

(See also exploded view below)

Survey of gears for military and civilian

MC's

|

Model

|

WD16H

and civil 16H and Big4 |

WDBig 4 |

|

|

Civ 16H and Big4 |

WD16H |

|

AXLES |

NUMBER |

PART # |

PART # |

NUMBER |

-- |

PART # |

|

Main Axle |

N3030 |

3318 |

3319 |

-- |

-- |

3319 |

|

Layshaft |

N3031 |

9672 |

3320 |

-- |

-- |

3320 |

|

GEARS |

NUMBER |

TEETH # |

|

NUMBER |

TEETH # |

PART # |

|

Main Gear wheel |

N8034 |

24 |

9673 |

N8047 |

25 |

2266 |

|

Layshaft Pinion |

N8035 |

18 |

9678 |

N8046 |

17 |

2268 |

|

Main Axle Sliding Pinion |

N8036 |

22 |

3322 |

N8162 |

21 |

2031 |

|

Layshaft Free Pinion |

N8037 |

20 |

9679 |

N8163 |

21 |

2034 |

|

Main Axle Free Pinion |

N8040 |

18 |

9676 |

N8160 |

16 |

2032 |

|

Layshaft Sliding Pinion |

N8041 |

24 |

9680 |

N8161 |

26 |

2035 |

|

Main Axle Pinion |

N8044 |

13 |

9677 |

N8048 |

12 |

2267 |

|

Low Gear and Kickstarter Wheel |

N8045 |

29 |

9681 |

N8049 |

30 |

2669 |

Survey of

Sprocket teeths on the various positions

|

Model |

WD16H

|

WDB4

|

Civil 16H and

B4 (solo) |

Civil 16H and

B4

(sidecar) |

|

PART |

|

Engine Sprocket |

18 |

18 |

19 |

17 |

|

Clutch |

42 |

42 |

42 |

42 |

|

Gearbox Axle Sprocket |

19 |

19 |

19 |

19 |

|

Rear Wheel Drum Sprocket |

43 |

52 |

42 |

42 |

According to EM Franks (see ref

page), "For civilian purposes a 21 or 22 tooth engine sprocket

should be fitted to the sidecar wheel drive outfit (W.D. B4), and a 19 tooth

to the W.D.16H machine."

Total transmission ratio’s between crankshaft and rear wheel drum

|

Model |

WD16H |

WD Big4 |

Civil 16H,

Big4(solo) |

|

GEAR |

Norton |

Calculated |

Norton |

Calculated |

Norton |

Calculated |

|

First |

15,7 |

15,70 |

23,6 |

23,48 |

- |

11,78 |

|

Second |

9,35 |

9,39 |

15,3 |

15,26 |

- |

7,01 |

|

Third |

6,39 |

6,40 |

9,4 |

9,39 |

- |

4,79 |

|

Forth |

5,28 |

5,28 |

6,4 |

6,39 |

- |

4,88 |

I calculated the overall transmission ratio's

based on the actual numbers of teeths on all the gear wheels and

sprockets.

From this I came to slightly different values than actually given by

Norton. I guess the differences are caused by rounding off

variations etc.

Being actual hard numbers its impossible to calculate other values,

there are no 1/2 teeths possible.

I did not find any overall transmission values for the civilian 16H

and Big4's.

|

Chains

The table shows chain sizes as given in the

spare parts lists for both WD16H and WD Big4. When using other

sprocket sizes (see above), it may be necessary to adjust the

chain length accordingly.

|

PART

|

Chain size

old |

Modern |

no. of

links |

|

WD

16H |

WD B4 |

|

primary chain (front) |

1/2 x 5/16 |

428 |

74 |

74 |

|

secondary chain (rear) |

5/8 x 1/4 |

520 |

91 |

96 |

|

|

Dismantling and re-assembly of the Gearbox

Dismantling and re-assembly of the Norton 4 speed gearbox is

generally relatively straight forward when following the instructions given in

the Maintenance and Instruction Manual. There is no difference

between the 16H and Big4 boxes apart from the gear wheels.

There are some points of attention. The M&I

Manual does not give any figures for the total wear

allowed on the Bronze Clutch Thrust Washer. Additionally, the gearbox exploded

view of the M&I Manual shows a dished washer at the end of the main

shaft, which in many cases is missing in actual gearboxes, and

the same exploded view does not give the Main Gear Wheel Sleeve

Bearing Roller Retaining Washer, which is a crucial part in the

gearbox! (I have drawn this washer into the original gearbox

exploded view below, encircled by a red ring.)

The Clutch Thrust washer is the washer taking up

the reaction forces when the Clutch is operated. Its positioned on

the main axle facing the hardened steel ring that keeps the rollers

of the Main Gear wheel in place. (Main Gear Wheel Sleeve Bearing

Roller Retainer Washer).

The Bronze washer has three grooves in one face, which to be

correctly positioned should be facing towards the Main gear wheel

(Clutch). When these grooves are worn away, the washer needs to be

replaced. The Clutch Thrust washer has a thickness of approximately

7/32 inch (5,55 mm). Maximum permissible wear of the Clutch

Thrust Washer is 1,58 mm or 1/16th inch.

Investigation of the Clutch Thrust washer is indicated when the max

end float of the clutch itself exceeds the 1,6 to 2,38 mm. This can

be roughly inspected by pushing and pulling on the clutch in axial

direction.

End float of the main axle should preferably between 0,254 and 0,508

mm (0,01 - 0,02 inch). If the end float is still outside this range

while the Clutch Thrust washer is within the specified thickness,

the main axle should be shimmed behind the Clutch Worm nut.

This is where the elusive dished washer may be

become handy although flat shims will do the job as well.

The exploded view drawings of the gearbox in the Maintenance and

Instrucion Manual as well as various books, show a dished steel spring

washer at the end of the main axle. I personally have never found such a

washer in a gearbox, and wonder if they were actually used on all boxes,

or only the later ones. Its not given in the spare parts list of either

old or newer contracts or postwar civilian lists. The dimensions are I.D.

5/8", O.D. 1 7/16", steel thickness 1/64" and dished height 1/16"

(as

measured from an actual washer).

Main Gear Wheel Sleeve Bearing Roller Retainer Washer

and Felt Washer for Clutch Nut .

This hardened washer has the tendency to fracture. Two of the 3

gearboxes I have showed this to be the case. The washer is given in the

spare parts lists (all) under spare part no 3598 (Main Gear Wheel Sleeve Bearing

Roller Retainer Washer). I have however not been able to find

original replacements for them, and had them made from a cold work tool

steel (AISI D2 or UNS T30402) and hardened to 59 Rc. Remains of the

original were measured to be 60 Rc so I think I am close enough.

Felt Washer for Clutch Nut, part no. 9744 is also added to the

exploded view below.

Below also some pictures of various gearbox parts, (source:

Olav Jerzykowski) |

Click to enlarge

|

|

Clutch issues

Disengagement

A not uncommon problem encountered when using the MC is that at a

certain moment it appears the clutch cable needs regular adjustment

for a proper clutch release. This is usually caused by the loosening

of the central clutch nut. Contrary to the expectation in the

Instruction and Maintenance manual, a clutch puller is not always

required to remove it from the gearbox axle. A side effect of

a regular adjustment of the clutch cable length may be that at a

certain point, the clutch bolts eat metal away from the outer

primary chain case. The clutch itself is a fairly simple but

effective part.

The original WD clutch back plate was a relatively thin pressed

sheet metal part of even thickness. Post war AMC clutch back plates

are much thicker parts with a chamfered outer edge. They do fit on

the earlier machines as well but there will be even less clearance

between backplate and the primary chain case.

Another source for

disengagement problems can be caused by spring force differences and

possible damages to (almost) sliding faces between cup and stud. The end

plate disc should lift squarely from the plates.

New clutch

plates

I hear many Norton riders complain

about the bad working of the clutch after installing new clutch plates.

New clutch plates made by/to fit AMC upto 1959 fit in WD and other

pre-war Norton clutches.

It keeps dragging a lot. I found out years

ago that the newer plates were slightly thicker than the older ones,

resulting in a minimum play when pulling the clutch lever. This usually

results in continuously dragging plates, leading to gear change

problems, especially when trying to find the neutral position while

standing still. My solution to the

problem has been to just remove one steel and one fiction plate. The

plates will get more "room" to disengage, reducing the drag to a

minimum. With good springs there will not be any slippage, and the front

wheel of the bike can still be lifted from the ground by a sudden clutch

engagement.

If the clutch does show some slippage, the springs could be replaced by

longer ones or some washers can be added

at the bottom of the spring cups, making up some of the thickness of the missing

plates.

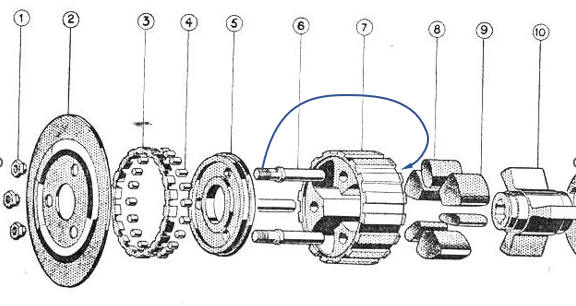

Clutch

assembly

When looking at the exploded view of the clutch, it suggests that

the Clutch Spring Studs (6) are mounted onto the Clutch

Body Back Cover Plate (5) but in actual fact they are used to bolt

the Clutch Body (7) down through the Clutch Body Back Cover Plate

(5) to the

Clutch Back Plate (2) where they are fixed with the hexagon flanged

nuts (1).

|

|

|

|