|

During the years I have the WD16H, and while making this website and

answering people on various items, I found that a number of parts are not

given in the spare parts lists or described in the Maintenance &

Instruction Manuals that I have. The consistency with which they are not given is puzzling. Nobody

bothered to mention it, or Norton was not interested in correcting it.

Other parts are prone to failure but their failure is not

always obvious. Additionally it is helpful to have some dimensions of

parts not so readily available anymore like friction discs for front

fork and steering damper.

The engineering of the bike is lovely crude. Any superfluous oil is

just discarded on the road through multiple copper pipes. Length and

routing of those pipes hardly ever are original nowadays. They tend to

break off or have been cut short after kinking. If you have to make new

ones, some guidance is given on how to get the original look again. When

building up a bike from parts, some of them are difficult to find as

they are not clearly visible in the illustrated parts list.

Also some special tool are given which can be made to ease

tinkering on the bike.

I hope my experiences can be of help. I expect this to become a small list in the end.

It is not always to be taken as advice. It is always your own decision and

responsibility if you follow what I did/do.

MYSTERIOUS PARTS

Crankcase breather valve.

To alleviate the pressure differences which develop in the crankcase when

the piston is going up and down, a pressure relieve system is usually

utilized. On the 16H and Big 4 engine, this consists of two supplementary

systems, one timed version breathing through the driving side flywheel

into a cavity in the crankcase blowing out of a hole underneath the

driving shaft behind the primary chain case and one ball valve type

breather on the left hand side of the crankcase onto which a copper pipe

is mounted spitting excess oil onto the rear chain and relieving

pressure at the same time. The ball assures that the oily mist is

going one way only.

This copper breather tube, steel ball

valve and the brass nipples are not very obvious in the spare parts list.

It is listed under Transmission as "Crankcase breather, complete with

Pipe" part no. 9531. It would be more appropriate in the Engine

section!

The Maintenance and Instruction manuals do refer to a valve,

without any further description of the configuration and working.

Over time when engines wear and more pressure develops due to gasses

bypassing the piston this breathing system becomes more important (also

less adequate).

At the same time wear occurs on the screw in the valve reducing the

available aperture for the air to blow through. The steel ball hammers

into the brass and deforms the screw end, which will therefore reduce

the possibility for breathing while you actually would need more. This

will likely result in a leaking engine at all kinds of places.

Pictures below show the valve construction and the wear on the central

screw.

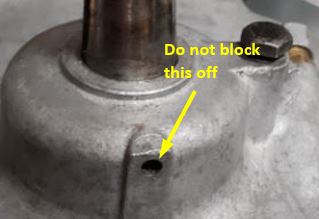

Bottom view crankcase breather

valve

Top view crankcase breather valve

wear on breather bolt, new, medium, severe

Strangely enough, Norton never described this wear nor an

inspection of the valve and similarly no information on the play the

ball should have in the valve.

I assume the ball should lift just enough to have the same aperture surface as the

the hole surface in the screw which is obtained around at 1-1,5 turn from

fully seating.

Overall, the efficiency of this system is to be regarded as theoretical

and unlikely to be working at all rpm's as intended as at higher speeds

the steel ball is supposed to be vibrating at the engine rpm frequency

but its mass may not be willing to comply.

One note of caution, some people block-off the timed breathing aperture

in the crankcase behind the primary case because there will be some oil

dripping from it, especially when the engine is prone to wet-sumping due

to worn oil pump gears and/or prolonged storage.

This is not correct and may lead to more oil consumption/leakage as it

halves the breather capacity.

Rubber, felt and leather washers/distance pieces.

Many bikes have lost their rubber, felt or leather washers over the years.

Many people don't even know there should be any at all. The M&I manual

does sometimes mention them, but although mentioned in the spares lists, they are relatively mysterious.

Between the primary chaincase and the engine crankcase a

rubber washer was used initially but changed to leather from 1942

onwards. Between the primary chaincase and the gearbox a

felt washers was applied.

Felt washers were further used for: clutch nut, gear

change pawl carrier, wheel hub bearings (both sides), inside primary chaincase

between footrest tube and outer casing. Between the top frame tube and

the petrol tank 2 sheet rubber patches were applied, on "later"

bikes (post 1942) these rubber patches were replaced by pieces of felt.

I also added a non standard felt washer between the magneto and the timing chain

case.

A special hard rubber washer "system" was used on the bolt holding the

Rear Mudguard to the Rear Mudguard Chain Stay Bridge (frame cross brace). The bolt is simultaneously

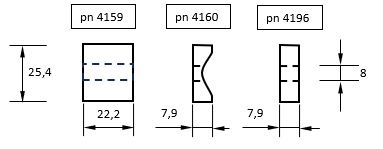

fixing the Oil Tank Top Attachment Clip (pn 3590). This system consisted

of multiple thick "washers" with 3 different part numbers, 4159,

4160 and 4196, below drawing gives the dimensions as found.

The exact application is difficult to state as even the most original

MC's found had different solutions. One logical sequence found was

short length on mudguard side, channelled version for ribbed mudguard,

other for plain mudguard, followed by long version, a metal washer,

cross tube, oil tank attachment clip, washer and bolt.

Gearbox main axle dished spring washer

The exploded view drawings of the gearbox in the M&I manual as well as various books, show a dished steel spring

washer at the end of the main axle. I personally have never found such a

washer in a gearbox, and wonder if they were actually used on all boxes,

or only the later ones. Its not given in the spare parts list of either

old or newer contracts or postwar civilian lists. The dimensions are I.D.

5/8", O.D. 1 7/16", steel thickness 1/64" and dished height 1/16" as

measured on an original sample.

Clutch Roller Cage with Rollers

The number and dimension of the rollers is not given in either spares

list or maintenance manual. From the M&I manual it can almost be deduced

how many with a small margin of error. In actual fact, 20 rollers are

used 1/4" x 1/4". Post war AMC clutches used 15 rollers of the

same dimension. Not quite sure why the more powerful postwar

machines had less rollers. Only thing I can assume it was an overkill to

use 20 or the material properties had been improved.

Clutch Back Plate

The original military WD16H and Big 4 backplate was a sheetmetal stamping

with a thickness of approx 3 mm. Post war, the early AMC backplates were machined

and have a greater thickness. Later AMC backplates (post 1957?) with incorporated

friction parts may work as well but with the correctly associated plain Clutch

Sprocket. Drawback of using AMC backplate is that the clutch becomes

wider and will interfere with the inner chaincase more easily. A lot of tweeking

may be required to get the parts into such position that they do not rub against each

other.

Kickstarter Axle cork oil retainer washer (3810)

To prevent the oil leaving the gearbox along the kickstarter axle there

is a cork washer fitting in a recess in the gearbox cover.

The washer p/n 3810 is not shown on the M&I manual exploded views.

People have replaced the cork with a proper size O ring.

If you do, make sure it is chemical resistant to the oil. NBR or Viton will

do the job.

Driving Side Main Bearing Distance Piece (4155)

In early 16H and Big4 spare parts lists (upto to 1942), this metal ring is not

mentioned despite the fact that they are mounted in all engines after

1935. It is placed between the two main bearings at the drive side of

the engine. It is a flat ring with an oil channel at the outer

circumference and 6 holes in the middle (up to 1940 roughly) or 4 recesses on one side

(later version). These recesses are shown in the exploded view of the

Big 4 M&I manual to face towards the inside of the engine. The

written text of "Fitting bearings to crankcase" however

gives no guidelines to the position of these recesses so it is possibly

not important. The exploded view of the engine in the 16H M&I manual

does not show this part at all.

Click picture to enlarge

Click picture to enlarge

Carburetter needle jet

The Needle jet in the 276 carburetter has been described in the

original AMAL specification sheets for WD16H and B4 as "standard". The Spare

parts lists and the VAOS lists describe it just as Needle Jet with part

number AM/4/061.

The Burlen Ltd company, (present official AMAL manufacturer, see links

page) stated that the "standard" part was actually the 1065. These were

not marked. For reason of optimisation, there are alternative needle

jets available

numbered, 105, 106, 107, 108 and 109. The number signifies the internal

diameter in 1/1000th of an inch.

Carburetter needle clip position

Something that crops up all the time is whether you count the needle

clip slot from the top down or bottom up. With all Amal carburettors the

clip position is top down. (ref The Burlen Ltd website).

Fork Spindle Knurled Adjusting Washers (3184)

The drawing of the front fork as given in the Maintenance &

Instruction manual is not completely correct. The drawing only shows 4

knurled washers (10) but it have to be 6 as stated by the spare parts

lists and logic. I adapted the drawing to show the two additional

washers (10) on the bottom rear spindle.

Click picture to enlarge

Click picture to enlarge

UNEXPECTED DIFFERENCES

Magdyno platform variations

When restoring a military 16 H or Big 4 from scratch, one

unfortunate finding could be that the timing chain as dictated by

the Magdyno sprocket does not run in line with the driving timing

sprocket.

When using the wrong platform, there is no gap between the rear of

the timing chain cover and the Magdyno. When using the correct

platform there should be a clear gap between those parts. I cannot

give an exact measurement for the gap as there are many variations

but some measured results are around 3/16" (4,7) mm. To prevent

muck to enter the timing chest through this gap I have made a

fitting felt washer mount between the Magdyno and the timing chain

with such dimension that it does not interfere with the rotating

Magdyno shaft and is not to obtrusive when looking at it from the

outside.

The in-line deviation will not happen (on military bikes) when

using the cast iron version as made during the war (casting number

12311), but it can happen when applying the aluminium version as

used before and after the war. The correct aluminium version has a

casting number 11699 on it. One incorrect aluminium version has a casting

number 13814 on it, there may be more aluminium casting numbers.

The civilian Norton part number changed from 3711 (pre war military

and civilian prior to 1938) to 3711A for the cast iron version to

A2/117 in 1946 and 1947.

The 1938/39 civilian Norton part number was 8918, but its not clear

yet if they deviated in dimensions or casting number and whether

they are identical to the pre war 1938/1938 civilian version.

There has also been a part number C2/117 but its not known (at this

moment of writing) in what sense it differs from A2/117 or 3711(A).

The number 13814 was found on a platform labelled C2/117.

NOT SO VISIBLE FAILURES (AND SPARES)

Main Gear Wheel Sleeve Bearing Roller Retainer Washer.

Pictures of the "exploded view" gearbox show that the rollers in

the main gear wheel are neatly housed. What it does not show is that the

rollers are closed into the main gear wheel by a steel washer, against

which the bronze clutch thrust washer rotates when activating the clutch.

Look at the picture given in the

gearbox and transmission

page where I added the washer for clarity.

This hardened steel washer has the tendency to fracture. Two of the 3

gearboxes I have showed this to be the case. The washer is given in the

spare parts lists (all) under no 3598 (Main Gear Wheel Sleeve Bearing

Roller Retainer Washer). I have however not been able to find

original replacements for them, and had them made from a cold work tool

steel (AISI D2 or UNS T30402) and hardened to 59 Rc. Remains of the

original were measured to be 60 Rc so I think I am close enough. See

Parts sketches for manufacture or reference page for dimensions.

Loosening clutch nuts

On some bikes, you see an additional disc in the large depression

produced in the primary chain case to house the clutch. This is usually

the result of adjustment of the clutch disengagement while actually the

clutch nut has come loose.

So if you ever have the urge to adjust the clutch disengagement stroke, first check the central

nut on the clutch. Despite the spring washer behind it, it loosens on

occasion.

OIL AND GREASE STUFF (See alo the

running a 16H or Big 4 page)

Oil non-return valves.

Anybody not having used his bike for some time will have experienced the

blubbering noises and heavy kick starter actuation when trying to start his

machine. I know, everybody has a perfect oil pump, but me?

The oil tank has drained itself into the engine

crankcase after finding its way past the gears of the oil pump.

A safe solution is to add a non-return valve into the oil line. Although

I made one myself, you can also buy them on the market.

An oil tap works but with rising age is not the best solution,

unfortunate experience!

Valve grease nipples.

One of the most amazing features on the 16H engine are its valves. There

are grease nipples on the valve guides as a token addition to subdue valve

stem wear. Initially I used to give them a squirt of high temp molybdenum

based grease. This usually resulted in a fairly sizable smoke curtain at

the beginning of a trip.

I stopped greasing them as I don't think it has any use. I am now about

25.000 miles further since I stopped greasing and it still works. I know

I don't have the maximum compression, and I don't go faster than 50 MPH

anyhow because that is a very uncomfortable speed on a dinosaur

suspension.

Oil regulating grub screw on top of timing cover

An often asked question reaching me is about the setting of the grub

screw valve on top of the timing cover.

The setting of this grub screw regulates the amount of oil being fed to

the rear of the piston/cylinder.

It is not properly described in the military Maintenance and Instruction

manuals people usually use as guide.

The setting of this was done at the factory and should normally not need

to be touched. After 60 odd years however some cleaning of the insides

may be required or the workmanship of previous owners needs to be

checked.

The standard setting of this screw is one turn from the fully closed

position. (According to WC Haycraft in 1936 and EM Franks in 1952).

Its difficult to say if this is still correct for all engines, but

depending on the state of the engine it may need some adjustment.

It should be adjusted such that there is a minimal amount of smoke

coming from the exhaust. As the smoke from the exhaust does not only

come from this setting, its a setting with lots of possible positions.

The standard setting is therefore the most likely correct one.

|